Performance Polyethylene Resins

Explore our industry leading Exceed™ S, Exceed™ XP, Exceed™ and Enable™ performance polyethylene (PE) resins ― as well as our LLDPE, LDPE, HDPE, and Paxon™ HDPE resins, and specialty copolymers ― which have been designed for a broad range of polyethylene applications.

Experience tomorrow’s performance today with ExxonMobil PE products and solutions.

Performance polymers

When you are looking for more stable operations and better line output, Enable™ PE resins deliver excellent processability and bubble stability with HAO properties in a single resin.

Learn more >

When your applications demand the ultimate in stiffness and toughness, and easy processing is essential, the Exceed™ S resin portfolio is the solution that elevates performance, while simplifying operations.

Learn more >

If your applications are highly demanding, the Exceed™ XP portfolio of resins offers the extreme toughness needed to deliver truly differentiated solutions.

Learn more >

For your applications that need a combination of outstanding sealing and best-in-class optical properties, Exceed™ PE resins are the answer.

Learn more >

Core resins

Our broad portfolio of HDPE resins provide a suite of solutions for machine direction oriented (MDO) films applications as well as blow molding, roto molding and injection molding.

Learn more >

Our broad portfolio of LDPE offers a combination of high melt strength, excellent optical properties, and outstanding shrink performance.

Learn more >

Our broad portfolio of general purpose LLDPE resins can meet a wide variety of performance requirements over a broad range of density and melt index.

Learn more >

Specialty copolymers

Escor™ ethylene and acrylic acid (EAA) copolymer resins offer excellent adhesion to polar substrates without the need for primers.

Learn more >

The most thermally stable of all high-pressure PE copolymers, Optema™ ethylene methyl acrylate (EMA) copolymers can be processed by extrusion coating lamination, blown/cast monolayer and coextruded films, injection molding, sheet or profile extrusion, blow molding and foam extrusion.

Learn more >

ExxonMobil™ ethylene n-butyl acrylate (EnBA) copolymers adhere to a variety of polar substrates including paper, polyesters, ionomers, PVdC and unplasticized PVC.

Learn more >

Escorene™ ethylene vinyl acetate (EVA) copolymers are used in extrusion film processes for applications including packaging, surface protection and greenhouse covers – and in photovoltaic cell encapsulation. View these thermoplastic resins.

Learn more >

Alpha olefin copolymers for flexible packaging, molded/extruded products, wire and cable, and foaming compounds.

Learn more >

Video center

Video: High performance polyethylene portfolio

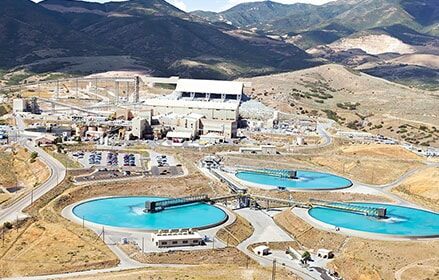

Supplying solutions to the primary and secondary packaging, agricultural and building and construction markets, the ExxonMobil polyethylene portfolio offers an extensive range of performance polymers as well as specialty co-polymers and additional polyethylene grades.

Industries and applications

Featured resources

-

Whitepaper: Future trends in the flexible packaging industry

While demand for chemicals and plastics is being fueled by a growing global population and middle class, other trends are affecting the packaging landscape. Read ExxonMobil’s view of what will impact the flexible packaging industry moving forward.