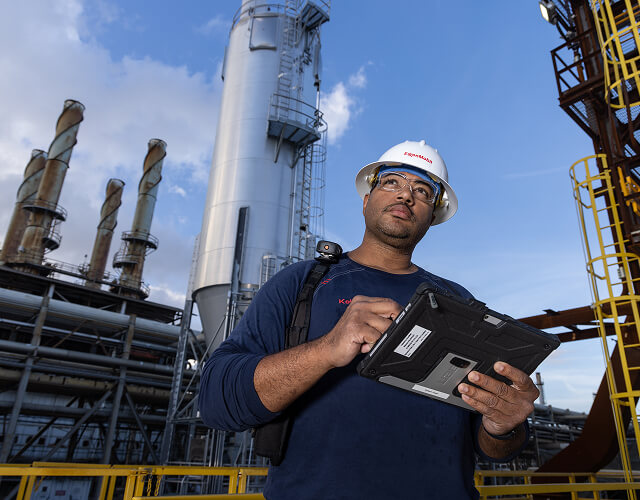

ExxonMobil’s approach to sustainability

ExxonMobil is committed to creating sustainable solutions that improve quality of life and meet society’s evolving needs in ways that help protect people, the environment, and the communities where we operate. The corporation’s approach is reflected in the “Sustainability” section of our website.

Expanding the plastics life cycle

Design for recyclability

We offer plastic film solutions designed to support recyclability in the few communities with collection programs and facilities that accept plastic film. Actual recyclability depends on local systems and package design.

Incorporation of recycled content

Our high-performance polyolefins can help customers incorporate recycled content while maintaining mechanical properties and performance.

Certified-circular polymers

Our certified-circular polymers, supported by our Exxtend™ technology, help drive the demand for using plastic as a valuable feedstock. Certified-circular polymers are virgin quality polymers that are accompanied by an ISCC PLUS “Sustainability Declaration” that matches the mass of virgin quality polymers that we sell to a corresponding amount of plastic that we transformed back into usable raw materials through advanced recycling. Certified-circular plastics do not represent specific amounts of GHG emissions or recycled content.

Delivering economic benefits

Agriculture

Automotive

Building & construction

Consumer products

Energy

Hygiene & personal care

Industrial applications

Packaging

Supporting our customers with innovative solutions

Featured resources

Exxtend™ technology for advanced recycling

ExxonMobil is supporting a more circular economy for plastics through Exxtend™ technology for advanced recycling. At the forefront of evolving demand, Exxtend technology is a foundation for certified-circular polymers* that can help our customers advance their sustainability goals.

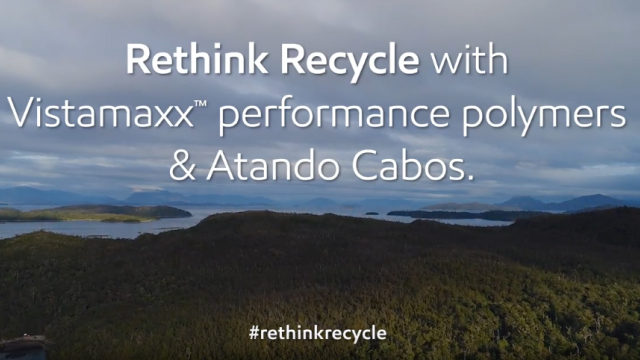

Atando Cabos: Creating change in Patagonia

Discarded plastic fishing ropes were polluting the delicate ecosystem of Patagonia. Learn how ExxonMobil worked with Atando Cabos to find a solution. By using ExxonMobil’s Vistamaxx performance polymers to help compatibilize PE and PP, discarded plastic fishing ropes in Patagonia can be turned into high-quality end products.