Helping doctors and nurses breathe safely

That's why an ExxonMobil team of experts in chemicals, materials science and manufacturing is offering their experience to help a collaborative effort organized by the Global Center for Medical Innovation. By quickly connecting its customers to solution providers, ExxonMobil helped create a new supply chain to respond to the medical needs in hospitals across the country.

This collaboration, which represents industry, academia and government, is rethinking how protective medical equipment, specifically face shields and face masks, is made.

All this happened in just a matter of days. So far, 50,000 face shields have been produced, and production facilities are ramping up to manufacture upwards of 170,000 more per hour in the coming days. The collaboration has also produced models for a new, reusable face mask design that will address the shortage of N95 protective masks.

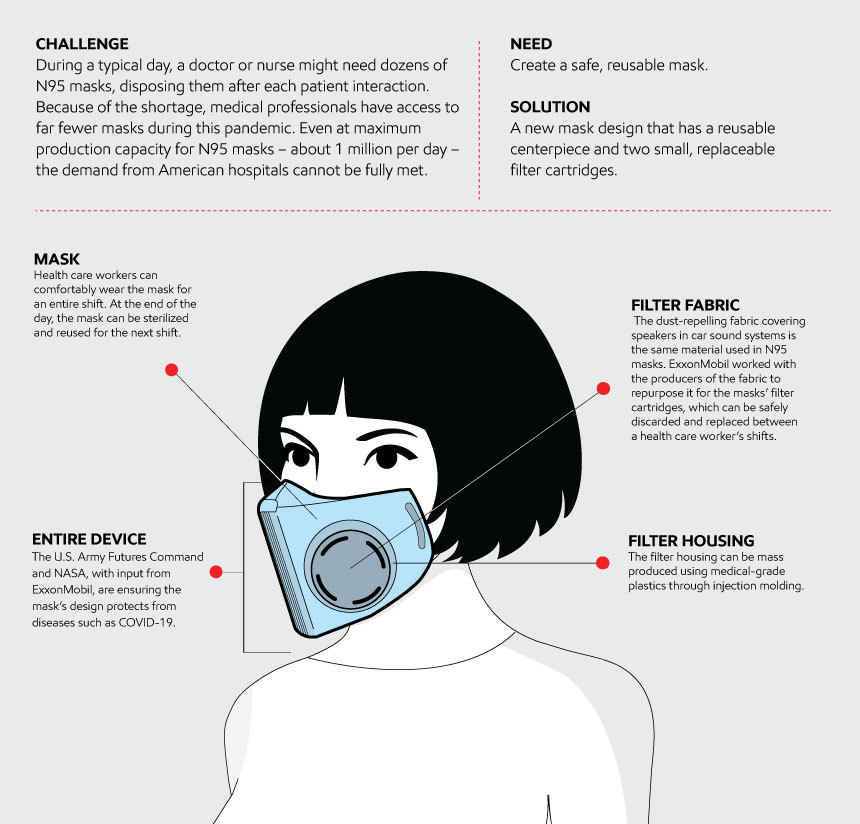

Here’s a look at that newly designed medical face mask and what makes it an essential tool in fighting the spread of the coronavirus.

More information on polymers, including product data sheets and gradeslates, and other innovative ExxonMobil Product Solutions healthcare solutions.

-

Products

ExxonMobil Product Solutions provides better building blocks for a wide range of chemical and polymer products that enhance the quality of life around the world.

Learn more -

Healthcare and medical

ExxonMobil Product Solutions is a long-term supplier to the healthcare industry with highly specialized products and focused technical service.

Learn more -

Medical nonwovens

Improve barrier performance, fit and fabric comfort in medical nonwovens with a wide range of products from ExxonMobil Product Solutions. These include Exceed™ high performance PP, ExxonMobil™ PP, Vistamaxx™ performance polymers and polyethylene products, including Exceed™ performance PE polymers. Applications include surgical drapes and gowns, medical protective gowns, face masks, shoe covers, disposable bedding and hospital apparel, sponges, pads, wraps, and filtration media.

Learn more

Read more

-

Our Coronavirus response

ExxonMobil is working to help meet the needs of health care professionals fighting this pandemic on the front lines, as well as those socially distancing themselves at home. While those needs continue to evolve, the company remains focused on working to meet global energy demand.

-

A new collaboration to fight COVID-19

When it comes to fighting the COVID-19 pandemic, it doesn’t matter the size of the company. Everyone has a role to play. For ExxonMobil – one of the world’s largest producers of isopropyl alcohol (IPA), a key ingredient in medical hand sanitizer – it means getting the product to where it’s needed most.

-

Producing solutions for frontline professionals

ExxonMobil is maximizing its production of the high-performance polymers used to make face masks, surgical gowns and other critical medical supplies for those treating patients with COVID-19, the disease caused by coronavirus. The company’s plants around the world manufacture the building blocks for plastics, like polypropylene and polyethylene.