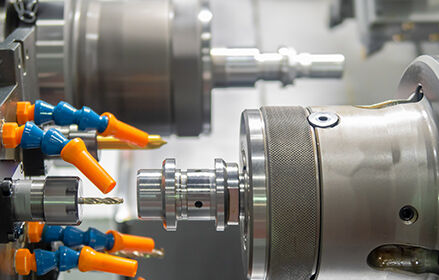

Metalworking

- Product performance

- Protection of employee and user health

- Environmental responsibilities

What application are you looking for?

- Improved annealing properties that reduce the potential of production rejects

- FDA compliance for use in the production of food-packaging foils and sheets1

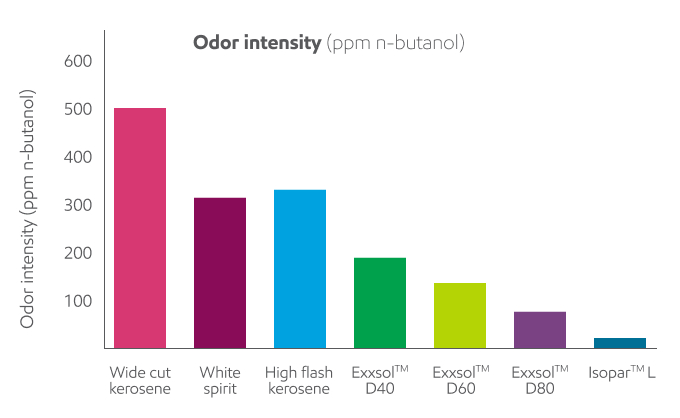

- Low odor to ensure good working environment

1 FDA 21 chapter 178.3910 (a) and (b) regulations. This webpage is not the official source for regulatory claims. For regulatory compliance statements, please contact Customer Service

- High degrees of quality and consistency for reliable forming fluid formulation performance

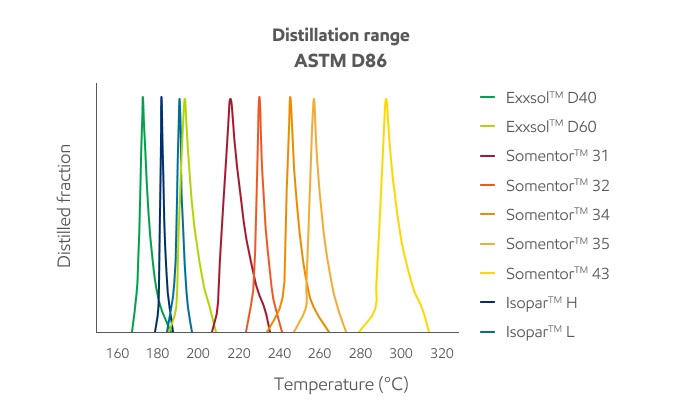

- Narrow boiling range for optimized formulations and drying times

- Choice of boiling ranges and flash points allows for

tailored fluid formulations (select from wide range of

evaporation rates & viscosities)

- Exxsol D: lower boiling point, faster evaporation rate

- Somentor: medium to high viscosity with higher flash point

- Isopar: narrower boiling range

- Low aromatics

- A balance of tailored drying times, viscosity, lubrication and safe operating conditions

- Good spreading and wetting properties

- Low aromatic content resulting in low odor, lower toxicity

Improved comfort

- Simplified operations, no secondary cleaning step is necessary

- Very low viscosity formulations for fast and uniform spreading

- Enable the formulation of outstanding self- evaporable oils

- Comply with selected food contact applications

- Result in fast and uniform spreading of the formulated oil on metal parts

- Low electric conductivity for spark control

- High flash points for great safety margins and applicability in higher-power sparking applications

- High thermal and chemical stability for long fluid life, better fluid integrity, fluid reuse and performance