Exxon™ bromobutyl

Exxon™ bromobutyl rubber is derived from halogenating butyl rubber with bromine in a continuous process. Structurally similar to Exxon™ chlorobutyl rubber and produced through the same halogenation process, Exxon™ bromobutyl rubber provides faster curing speed than regular butyl, and chlorobutyl. Our extensive product portfolio offers a variety of solutions leading to more flexibility while addressing compounding and vulcanization needs.

We take your needs seriously - and we respond all year long. Thanks to our manufacturing sites distributed all over the world you can count on high quality service delivery all year long. Our technology team makes their expertise available at your service. With centers located in the U.S., Europe, India and China, our experts are prompt to guide you towards the best solution for your business and your daily needs.

Performance and benefits

- Wide vulcanization versatility for a flexible and optimized curing process

- Good adhesion and compatibility to other general purpose rubber, suitable for the most appropriate compounding solutions

Industries and applications

-

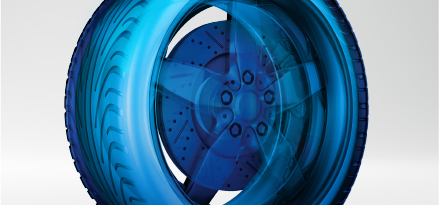

When it comes to tires, innerliners can make the difference in fuel efficiency, which can result in a reduction of CO2 emissions.

-

The pharmaceutical industry’s development of new medical drugs and medications calls for a safe delivery of high-quality stoppers.

-

Across many industries, a variety of applications ranging from hoses, adhesives & sealants, sporting leisure, and general rubber goods rely on butyl rubber.