Butyl

Eyes on the present, and always preparing for the future.

In this ever-evolving society, it’s important to be able to count on a reliable partner. With more than 80 years of experience, we produce butyl rubber to make it possible for key industries, such as tire manufacturing, automotive, and pharmaceutical to adapt quickly to the changes of today’s needs and future challenges.

Always by your side.

Our customers need a consistent basis of raw material delivered on time. This is necessary in order to ensure a successful business growth while mitigating potential production disruption.

That’s why we are committed to providing customers with dependable, high quality solutions throughout the year, along with technical support and expertise, anywhere in the world. With warehouses and technology centers positioned globally and our manufacturing plants in the U.S., EMEAF and Asia Pacific we offer the highest level of production flexibility.

Considering the needs of each player across the value chain.

We listen, collaborate, and engage with all of our customers, and we take every player and their needs along their value chain into consideration. We analyze what matters within their specific industry, so that we can adapt and efficiently respond to their needs. This is crucial to be able to deliver high-performance, top-notch quality material for our customers and stakeholders, that also addresses the industry’s and the policy makers’ concerns and requirements.

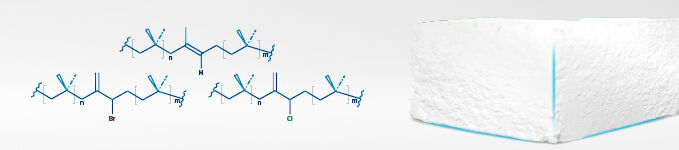

Products

-

Exxon™ butyl rubber (IIR) ensures excellent air-barrier, weathering resistance, aging resistance, vibration damping and good compression set.

-

Exxon™ chlorobutyl rubber (CIIR) provides an improved compression set and better resistance to heat, ozone and flex fatigue compared with regular butyl rubber, while maintaining the same excellent air-barrier properties.

-

Exxon™ bromobutyl rubber (BIIR) provides faster and more stable cure through additional carbon-carbon cross-linking compared with regular butyl rubber, while maintaining the same excellent air-barrier properties.

Discover us!

Industries and applications

-

When it comes to tires, innerliners can make the difference in fuel efficiency, which can result in a reduction of CO2 emissions.

-

The pharmaceutical industry’s development of new medical drugs and medications calls for a safe delivery of high-quality stoppers.

-

Across many industries, a variety of applications ranging from hoses, adhesives & sealants, sporting leisure, and general rubber goods rely on butyl rubber.

- Supporting our customers every step of the development journey

- Robust R&D studies and formulation testing

- Access to equipment for tire performance evaluation

- State-of-the-art lab facilities equipped with characterization tools for chemical/physical analysis of materials and compounds