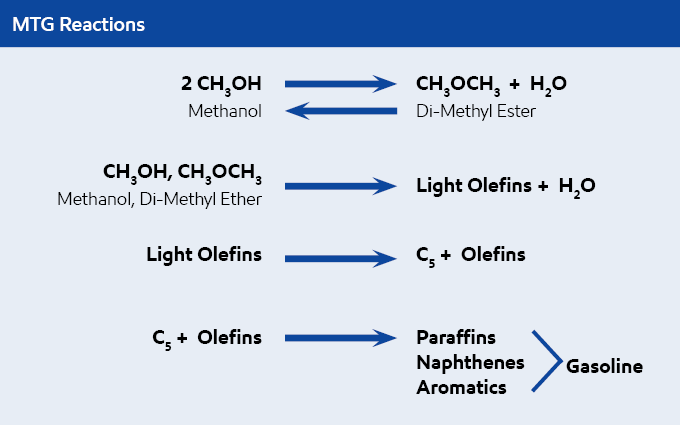

Methanol to gasoline (MTG) technology process

- Our Methanol to Gasoline (MTG) process selectively converts methanol to a single fungible liquid fuel and a small LPG stream.

- The liquid product is conventional gasoline with very low sulphur and low benzene, which can be sold as-is or blended with ethanol, methanol or with petroleum refinery stocks.

- This minimizes offsite and logistic complexity and investment for synthetic fuel distribution.

Key benefits

Proven process - Fluid bed MTG

Over years of extensive studies and pilot plant operations, we have developed both the fixed bed and fluid bed MTG processes.

Today, we focus on actively licensing fluid bed MTG over fixed bed MTG. Compared to fixed bed MTG, fluid bed MTG demonstrates overall advantages in CAPEX, OPEX, operation reliability, steady product quality, carbon intensity, and more.

The unique MTG catalyst is the science that limits the synthesis reactions to ~11 carbons, which is exactly the gasoline range.

In the fluid bed design, raw methanol feedstock, including typical 4wt% water and 96wt% methanol, is vaporized and superheated through a series of heat exchangers, then fed into the fluid bed reactor for conversion into hydrocarbons and water.

At the MTG reactor conditions, light olefins oligomerize into higher olefins, which combine through various reaction paths into paraffins, naphthenes, and methylated aromatics.

Proven pilot /demo plants

Our well-proven process and catalyst, rich ongoing pilot plant experience and high interest from customers have paved the foundation for the prospect of commercial scale units.

In the 1970’s, we studied the fluid bed MTG process in a 4 BPD (methanol input) pilot plant with very successful results. In the 1980’s, we took an extra step to conduct a 100 BPD (methanol input) fluidized bed MTG demonstration plant testing, also with very successful results.

In March 2015, ExxonMobil and Sinopec Engineering Group (SEG) announced a joint technology development agreement for advancement of fluidized-bed MTG technology.

Recently, we have licensed our fluid bed MTG process technology to renewable gasoline fuels projects in Chile.

Proven performance

The conversion of methanol to hydrocarbons and water is virtually complete with the product being a mixture of synthesis hydrocarbons and water with a limited amount of C₂- gases. Production yields, product qualities, and catalyst performance are stable during operation.

The liquid product is conventional gasoline with very low sulphur and low benzene, which can be sold as-is or blended with ethanol or methanol or with petroleum refinery feedstocks.

Featured resources

-

View highlighted news, events, technical papers and case studies below. To see our full collection of resources, browse our Library.