Rethink Recycle with

Vistamaxx™ performance polymers.

The recycling of plastics is a global growth market, and for good reason. Using lower-cost recycled input can create cost savings for businesses and is great for the environment. But different types of plastic may be incompatible and sorting them can be a costly and time-consuming process.

Vistamaxx performance polymers compatibilize PE and PP plastics, and allow them to mix in the melt, removing the need for separation. They also improve end product quality for high-value applications, including:

Key benefits:

Turning discarded milk tea cups to useful phone cases

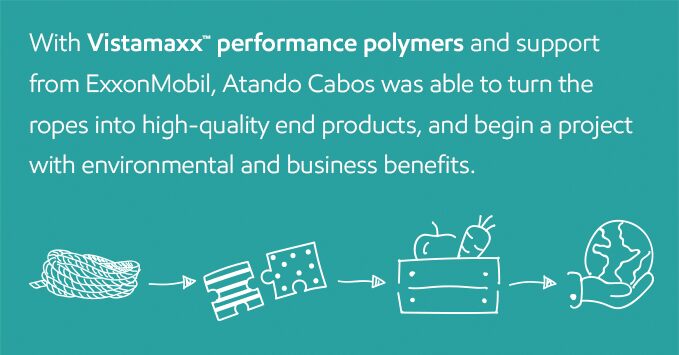

The beginning: Atando Cabos part 1

Building on Success: Atando Cabos part 2

Featured resources

-

Imagine the possibilities

Vistamaxx performance polymers let you stand out from competitors and increase your profitability.

Learn more -

Rethink Recycle

Vistamaxx polymers are a proven, cost effective solution that allows low-cost recycling, targeting high-value applications.

Download the PDF -

Cleaner beaches, useful products

See the data behind how Vistamaxx performance polymers made the Atando Cabos project happen.

Download the PDF

-

High value consumer products using recycled plastic

You can produce tough, durable and higher value products using recycled plastic. Take it from A to Z Textile Mills. They produced beautiful crockery, pails, crates, furniture, flasks and more using recycled plastic.

Learn how -

Case study: Tougher, more durable plastic pallets from recycled materials using Vistamaxx™ performance polymers

How See Hau Global incorporates recycled material in its plastic pallet production while maintaining the performance requirements of their pallets using Vistamaxx performance polymers.

Learn more