Why is advanced recycling important?

Plastics play an essential role in making modern life possible — from packaging that protects our food and extends its shelf life, helping reduce food waste, to lightweight materials that improve vehicle fuel economy, and medical supplies that help keep us healthy.

Their strength, versatility, and low weight make plastics the preferred choice across a range of critical applications. Yet with global recycling rates still below 10% and even lower for complex, hard-to-recycle plastics – including those that keep our food fresh – how do we maintain the benefits of plastics while addressing the challenge of plastic waste?

(1) Source: (National Overview: Facts & Figures on Material, Wastes and Recycling) EPA.com

Enter Exxtend™ technology for advanced recycling

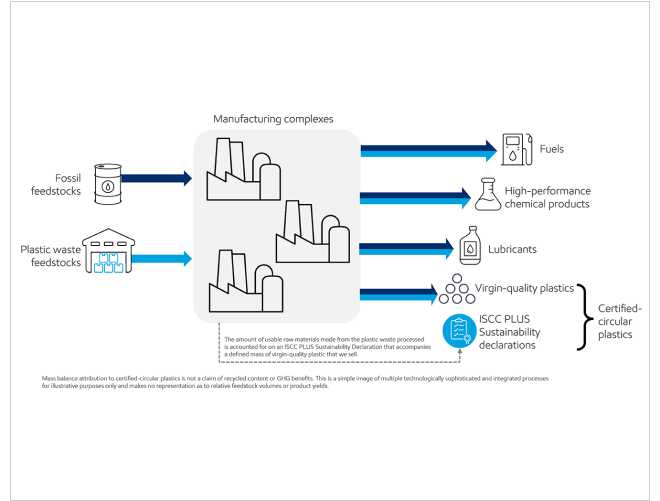

Helping give plastic waste a second life in a range of essential products including fuels, lubricants, and plastics. We offer certified-circular polymers, which are virgin quality polymers that are accompanied by an ISCC PLUS “Sustainability Declaration” that matches the mass of virgin quality polymers that we sell to a corresponding amount of plastic that was transformed back into usable raw materials through advanced recycling. Maintaining the benefits of high-performing plastics while supporting a more circular economy for plastic waste.

Why Exxtend™ technology can help meet the growing demand for a more circular economy

Mixed plastics

Innovation

Existing infrastructure

Material performance

*Certified-circular polymers are virgin quality plastics that are accompanied by an ISCC PLUS “Sustainability Declaration” that matches the mass of the virgin quality plastics that we sell to a corresponding amount of plastic waste that we transformed back into usable raw materials through advanced recycling.

Collaborating with Cadbury Australia and Amcor in the drive for a more circular economy for plastics

To support their circularity goals, Cadbury Australia and Amcor collaborated with ExxonMobil to incorporate certified-circular polymers* into Cadbury’s core chocolate packaging portfolio. Leveraging Exxtend™ technology for advanced recycling, the project sourced approximately 1,000 tons of certified-circular polymers, diverting plastic waste that may otherwise have ended up in landfill or incineration.

The result: Food-safe wrappers that deliver performance and protection. The rollout began in early 2024, starting with chocolate blocks and expanding across the range of other chocolate packages. this collaboration is helping support an alternative to fossil-based feedstocks while maintaining quality and shelf appeal. A meaningful step forward in the journey to a more circular economy for plastic packaging.

What is mass balance attribution?

In short, it is an accounting process that can be used in complex value chains like ours in which one input (e.g., plastic waste) is mixed with other inputs in a multi-output system. This approach helps our customers match the volume of their certified-circular polymers* purchase to a corresponding amount of plastic waste that was transformed into usable raw materials though advanced recycling. The certificate we provide our customers is not a claim that our certified-circular polymers contain any “recycled content” or GHG emissions benefits. Rather, the certificate represents an assurance that we followed a robust mass balance attribution system that is certified by a third-party on a feedstock basis.

Mass balance has been used in other industries, such as forestry and food products, for many years. A good analogy is to the accounting process used in purchasing renewable energy, like solar or wind power. Often referred to as “green power,” many residential consumers willingly pay a premium for this service from their electricity supplier. However, the useable electricity reaching their homes doesn’t flow through a separate cable from a solar farm or wind turbine. Instead, it travels through a vast network of power plants, transmission lines, and distribution centers that form the electrical grid. The electricity generated by commercial solar farms and wind turbines mixes with that from coal, natural gas, and nuclear power.

*Certified-circular polymers are virgin quality plastics that are accompanied by an ISCC PLUS “Sustainability Declaration” that matches the mass of the virgin quality plastics that we sell to a corresponding amount of plastic waste that we transformed back into usable raw materials through advanced recycling.

Accompanied by an ISCC PLUS “Sustainability Declaration”

To help brand owners and consumers make more informed choices, our certified-circular polymers* come with an ISCC PLUS “Sustainability Declaration”. This independently verifiable document provides transparency into how plastic waste is used as a feedstock and allows brand owners to credibly communicate the benefits of the products they bring to market. It also gives consumers a clearer understanding of how their purchasing decisions can support a more circular economy for plastics.

Under the ISCC PLUS framework, our Exxtend™ technology applies the “determined by mass” and “certified free attribution” options within the mass balance methodology. This allows the mass of plastic waste we process through our advanced recycling process, less manufacturing losses, to be attributed to the mass of certified-circular plastic we sell. This does not represent specific amounts of greenhouse gas emissions or recycled content but rather it reflects the recovery of useable raw materials from plastic waste that might otherwise be lost to landfill or incineration.

*Certified-circular polymers are virgin quality plastics that are accompanied by an ISCC PLUS “Sustainability Declaration” that matches the mass of the virgin quality plastics that we sell to a corresponding amount of plastic waste that we transformed back into usable raw materials through advanced recycling.Want to learn more?

- diverting plastic waste from landfills and incineration into useful raw materials;

- monetizing plastic waste to drive better collection and sortation;

- supporting an alternative to fossil-based feedstocks;

- increasing the range of plastic products that can be recycled;

- contributing to the growth of the advanced recycling sector;

- propelling the increase of plastic recycling rates; and

- delivering new, certified-circular polymers* into important end uses such as food contact and medical supply.

- ExxonMobil sources its advanced recycling feedstock from a range of suppliers across the United States and internationally. As interest in alternative waste solutions grows, a market is gradually emerging around the collection and preparation of plastic waste suitable for advanced recycling. To ensure a consistent supply, ExxonMobil collaborates with companies specializing in waste management, material recovery, and feedstock processing. These partners provide post-use plastics—such as mixed materials, films, and contaminated items—that are typically unsuitable for mechanical recycling but well-suited for advanced recycling technologies.

- As the industry continues to evolve, ExxonMobil will continue partnering with companies providing innovative technologies and infrastructure to improve the efficiency and scalability of feedstock aggregation. This includes advancements in sorting systems, preprocessing methods, and logistics solutions that enable the transformation of large volumes of plastic waste into valuable raw materials for new products, supporting the development of a more circular economy.

Featured resources

Valgroup continues its plastic circularity journey with ExxonMobil’s certified-circular plastics* leveraging Exxtend™ technology for advanced recycling

Advanced recycling challenges the previous limits of plastics circularity by helping to increase the range of plastic products that can be converted into demanding applications. Combining innovation and commitment to a more circular plastics economy, Valgroup is at the forefront of expanding the options for solutions with sustainability benefits in its portfolio.

Advanced recycling: Helping address automotive plastic waste

End-of-life plastic from the automotive industry presents a complex challenge for recycling and waste management systems. Addressing automotive plastic waste requires a shift in mindset—from viewing it as a disposal problem to recognizing it as a valuable resource. Rather than ending up in landfills, these materials can be remanufactured into new, high-quality products such as fuel, lubricants and plastics.

A two-pronged solution for a single goal: Strengthening plastics circularity

How Exxtend™ technology for advanced recycling complements mechanical recycling methods to expand the range of recyclable plastic products

*Certified-circular polymers are virgin quality plastics that are accompanied by an ISCC PLUS “Sustainability Declaration” that matches the mass of the virgin quality plastics that we sell to a corresponding amount of plastic waste that we transformed back into usable raw materials through advanced recycling.